The amazing journey of a dialysis machine

More than one in two dialysis machines used worldwide is made by Fresenius Medical Care. The machines are produced to order and delivered to more than 120 countries around the world. A dialysis machine involves precision work. Its modular design allows for customisation to the needs of our patients. Delivery Down Under is therefore just a minor obstacle. Here is the log of a dialysis machine’s journey from our plant in Schweinfurt to its destination in the Australian Outback.

Ordered, produced and ready to go halfway around the globe

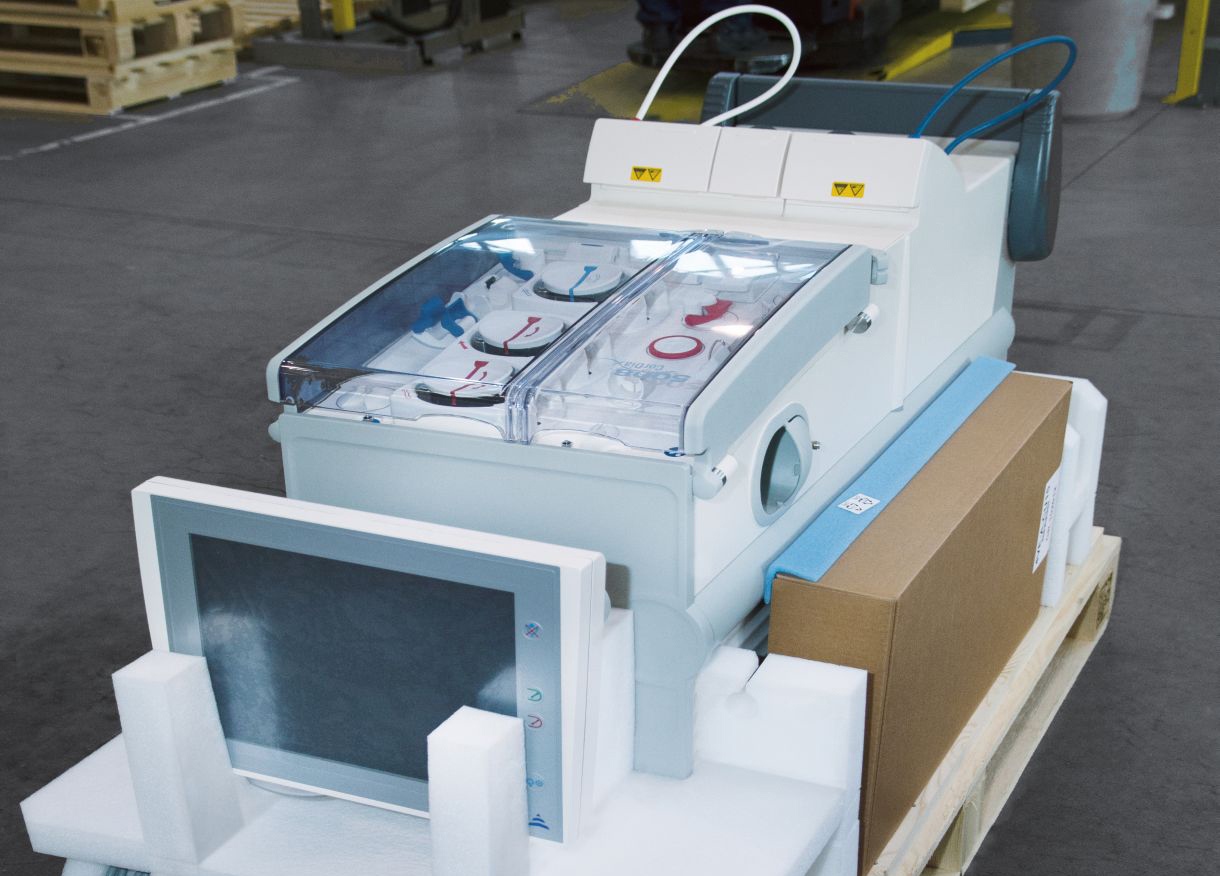

Safely packed

- A machine weighs 120 to 150 kg.

- The special packaging weighs around 25 kg.

We’ve thought of everything, including all the climate zones on the sea route. Each machine easily withstands frost and air humidity – a basic requirement. Even so, the dialysis machine is carefully packaged for transportation to protect it against falls, moisture and heat. The 8,000 components of a dialysis machine must all be well protected. Better safe than sorry.

On the road. The first and by far the shortest part of the journey is by road.

Loading

- Dialysis machines have been produced at the plant in Schweinfurt since 1979.

- The item is ready for dispatch just one to two weeks after ordering.

All set and ready for departure: one dialysis machine is going to Nepal and last week, a shipment was sent to Brazil. Ours is in line for Australia. It is loaded together with 45 other machines, as each container holds precisely 46 items. The journey can begin.

Next stop: Port of Hamburg

Train transfer

- Three hundred nine miles northwards by train

From asphalt to the rail track. Nearly all international exports go through the Port of Hamburg. There’s no hanging about. The workers at Schweinfurt’s container terminal guarantee that every container delivered to Schweinfurt by 5 pm can be loaded onto a ship on the Elbe the very next day. Our dialysis machine continues its journey that same evening. The freight train reaches the port in Hamburg early in the morning, one of 200 trains transporting thousands of containers there every day.

The containers are loaded. Ships sail from Hamburg to more than 950 harbours worldwide.

Ocean transport

- Nine million three hundred thousand containers a year are handled at the Port of Hamburg.

Loading at the gigantic logistics hub. The Port of Hamburg is the biggest transshipment point for rail containers in all of Europe. The port railway alone has a track network of 124 miles. On the other side of the transshipment point, 5,000 container ships call at the port each year. Our container is loaded onto the NYK Vesta. The ship, built in 2007, sails back and forth between Hamburg and Tokyo. The NYK Vesta, one of the biggest container ships in the world, has a capacity of around 7,000 containers. We are traveling part of the way on it: 8,562 nautical miles, to be precise. As far as Singapore. Ahoy!

Reloading onto feeder

- At the world’s largest port. It is 18.6 miles long and has more than 1,000 berths.

After 25 days at sea, we return to land for the first time at the Port of Singapore. Thirteen per cent of all dialysis machines produced in Schweinfurt are sent to the Asia-Pacific region. Nearly all of them make a stopover in Singapore. Despite the size of the port, the ships have to queue up. From here, it is “only” 4,791 miles to Sydney Harbor, our destination. The consignment is now transferred from an XXL container ship to an XL container ship known as a feeder, which only sails on the Pacific Ocean.

Day 39: arrival Down Under!

Delivery on-site

There’s one important thing left to do: before the dialysis machine reaches the customer, it has to make another stop in Sydney. At Fresenius Medical Care in Australia, it is completely unpacked and all functions are checked. Only then does it embark on the final stage of its journey: a road trip through the Outback. Our employees are on-site to set it up and install it.

Last stage

- Now it’s time for the last leg of the epic journey.

The machine will be transported overland to its final destination. From Sydney to Adelaide, via Alice Springs to Kiwirrkurra, a small village in an endless desert, thousands of miles away from Sydney, Melbourne and Perth.

Journey’s end

- Seventeen thousand, nine hundred sixty-two miles after leaving Schweinfurt!

Six weeks after dispatch, the dialysis machine is in operation. It improves the quality of life of dialysis patients even here, in the middle of the Gibson Desert in the Australian Outback, in a community with just over 200 inhabitants.