FX Dialysers

"Small details can make a big difference in terms of medical outcomes."

Why FX Dialysers make a difference

A dialyser is often referred to as an “artificial kidney" in dialysis treatment. Its function is to remove any excess wastes and fluid from the blood, when the patient's kidneys can no longer perform that task.

FX Dialysers have been used in more than 500 million treatments worldwide. As the world’s leading provider of dialysis products, Fresenius Medical Care aims to make a difference for patients and healthcare professionals.

Continuous innovation, combined with our commitment to the highest level of quality standards, ensure that our FX Dialysers portfolio is built to address the individual needs of patients.

FX portfolio

All FX Dialysers have the capacity to remove a broad range of uraemic toxins, effectively retain endotoxins and provide intrinsic biocompatibility.1

FX CorDiax

FX classix

FX paed

FX low-flux

A smooth treatment is the difference that allows us to focus more on the patient.

FX properties that make a difference

Several state-of-the-art technologies have been combined to create the distinctive functional properties of the FX Dialysers. Together, they make a difference in terms of beneficial patient outcomes, smooth handling and cost savings potential.

Smooth handling

The blue header, with its laterally placed blood inlet port, is designed to reduce the risk of kinked bloodlines, aiming at smooth handling and allowing healthcare professionals to focus on what really matters: the best care for patients.

Simplified work flows

The FX Dialysers are developed for system compatibility, perfectly fitting into automatic priming procedures with low rinsing volumes and short preparation times. In addition, there is no need to turn any FX Dialyser during the priming procedure. Moreover, the FX Dialysers have a removable label that can easily be attached to patient records, allowing for quick documentation.

Simplified work flows, user-friendly handling and short preparation time support the nursing staff’s daily work, freeing up resources to focus more on patients.

Improved clearances

Fresenius Medical Care’s Nano Controlled Spinning (NCS™) technology creates fibres with a highly defined membrane architecture. Precise nanoscale modulation of pore size, structure and distribution favours minimal resistance to solute transfer across the membrane and contributes to improved clearances compared to macro-design membranes.10,11

Additionally, the microwave fibre structure enables the homogenous distribution of dialysis fluid, supported by the FX Dialysers' inner housing’s pinnacle design. It prevents the channelling of the dialysis fluid and ensures that each fibre within the bundle is perfectly surrounded by the dialysis fluid.11,12,13

Enhanced performance

The optimised header design of the FX Dialysers ensures a homogenous blood flow path. Its geometry allows a spiral distribution of blood in the dialyser's header, preventing low velocity stagnation zones and resulting in enhanced performance.11

Setting the standard

Each FX Dialyser is individually sterilised by the unique INLINE steam sterilisation method. Both the blood and the dialysate compartments of the dialyser are rinsed continuously with steam at a minimum temperature of 121°C, followed by sterile water and sterile air.

Rinsing with hot steam assures a gentle sterilisation without the need for chemicals or irradiation, which may lead to increased cytotoxic14 and carcinogenic residues.15,16

Optimal use of resources

The INLINE steam sterilisation process allows for the efficient use of resources during preparation as well as a reduction of costs, since only 500 ml rinsing volume is required. The process

- includes a 100% fibre integrity test, aimed at minimising the risk of blood leakages due to fiber ruptures

- ensures that all FX Dialysers are already pre-rinsed and ready to use upon arrival, resulting in a short rinsing time and low rinsing volumes.

Best choice for high biocompatibility

Cytotoxicity is minimal after steam sterilisation, whereas it increases with gamma irradiation.14 Studies have shown that with steam sterilised dialyser membranes, less oxidative stress is induced to the patient’s blood compared to gamma sterilisation.17,18,19

Performance characteristics remain intact

Changes of the material properties can be observed after sterilisation with gamma irradiation, while the material remains intact in this respect when using steam sterilisation.20

Increased losses of albumin during dialysis sessions have been observed with gamma sterilised dialysers which had been stored for a longer time.14,21

Adding value across the entire life cycle

Fresenius Medical Care has implemented an approach based on the Life Cycle Assessment (LCA) methodology, which follows the structure and requirements of EN ISO 14040/44: 2006:

- Comprehensive assessment of a product’s environmental impact across its full life cycle, from materials supply to manufacturing, distribution, use and final disposal.

- Identification of improvement opportunities through environmentally sound processes, materials and design choices.

Lightweight material is essential for environmental sustainability

The advanced housing material of every FX Dialyzer is made of environmentally friendly and lightweight polypropylene. Due to the advanced material, FX Dialyzers are up to 50% lighter (before treatment) than dialysers made of polycarbonate22

This may result in improved end-of-life management by producing less waste23 and contributing to cost savings.

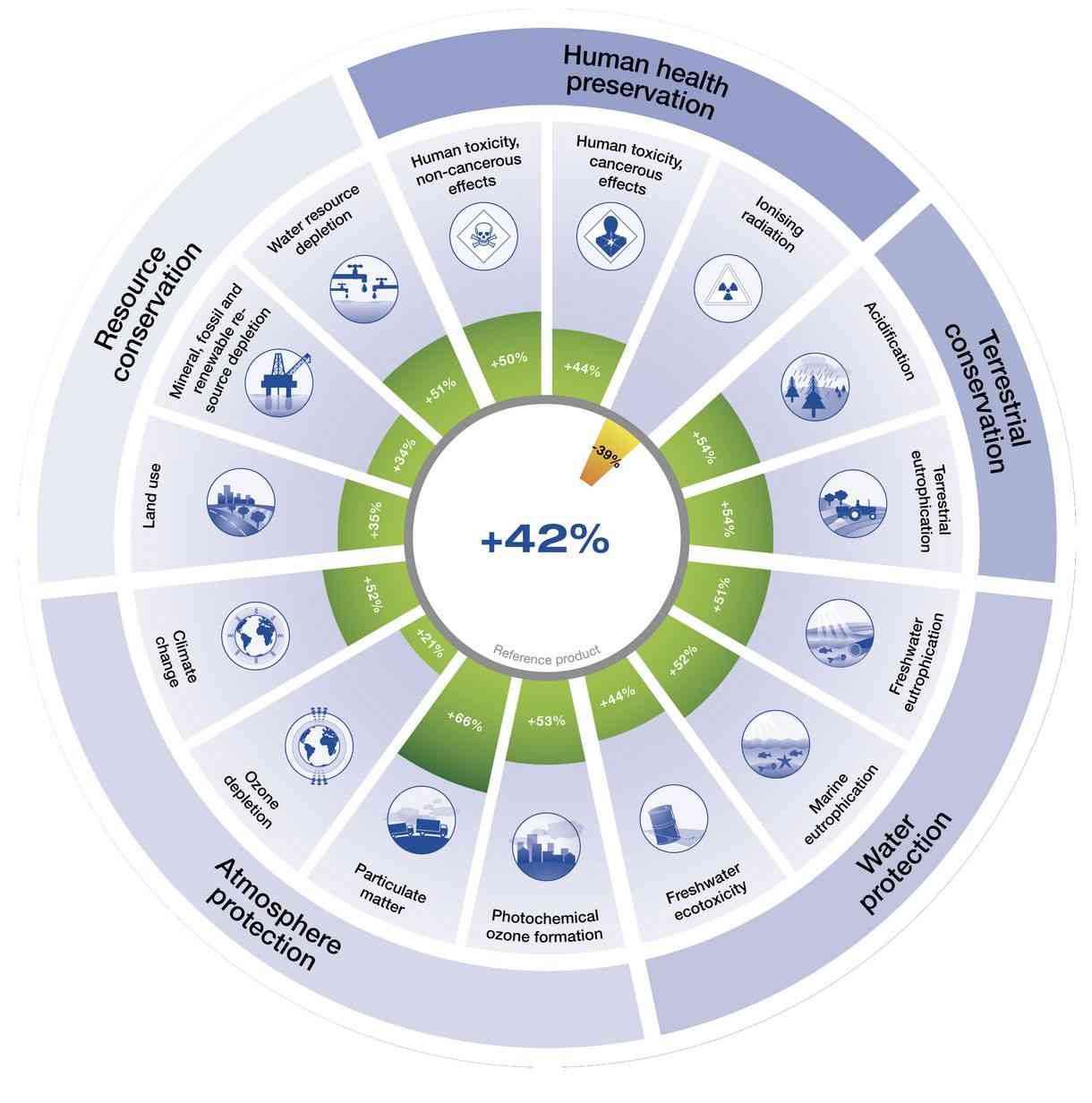

Improved eco-performance

Across 15 environmental impact categories24, the overall eco-performance of an FX Dialyzer (FX classix 80) is notably better — on average by 42% — compared to a reference dialyser made from polycarbonate (HF 80S).25

The difference is feeling confident throughout the entire treatment.

FX blue art project

Dialysers are life-saving pieces of medical and technological art. The advanced design of the FX Dialysers adds a dimension that reflects the thought, care and quality that went into its construction. As the most prominent visible characteristic, the color blue of the FX Dialyser caps became the inspiration point for our unique blue art project. We asked artists to interpret the benefits of the FX Dialysers in their own way — be it figurative or abstract, poetic or surreal, two- or three-dimensional — with stunning results. Each artist granted another level of meaning, a unique interpretation or a new perspective to apply to the distinctive functional properties of the FX Dialysers. Warm and sensitive, intellectual and meaningful approaches came to life.

Art gallery

Johannes Bruns

Svenja Nolte

Robert Lichtenberg

Jonas Goldmann

David Apel

Reliability and experience make a difference when seeking the best solutions.

Additional information relating to multiBic or Calrecia can be found in the critical care section of our product information page.

Adverse Events Reporting

Adverse events should be reported. Reporting forms and information can be found at

https://yellowcard.mhra.gov.uk/ or search for MHRA Yellowcard in the Google Play or Apple app store. Adverse events should also be reported to Fresenius Medical Care on 01623 445100.

UK/HEMA/FME/0922/0005 Date of Preparation: November 2022

1 Wagner S. et al., Nephrology Dialysis Transplantation (2017); 32 (3): iii615.

2 Bock A. et al., J Am Soc Nephrol (2013); 24: SA-PO404.

3 Maduell F. et al., Blood Purif. (2014); 37(2): 125-130.

4 Lim P. S. et al., Artif Organs (2017); Nov 27. doi: 10.1111/aor.13011.

5 Schindler R. et al., Clin. Nephrology (2003); 59: 447–454.

6 Weber V. et al., Artif Organs (2004); 28(2): 210-217.

7 Chazot C. et al., Nephron (2015); 129: 269-275.

8 Tsai I.J. et al., Pediatr Nephrol (2014); 29: 111–116.

9 Data from Fresenius Medical Care Deutschland GmbH: Comparison clearance values F8 HPS (effective surface area 1.8 m2) versus FX 8 (effective surface area 1.4 m2).

10 Ronco C., Nissenson A. R., Blood Purif (2001); 19: 347-352.

11 Ronco C. et al., Kidney International (2002); 61 (80): 126-142.

12 Külz M. et al., Nephrol Dial Transplant (2002); 17: 1475-1479.

13 Mandolfo S. et al., The International Journal of Artificial Organs (2003); 26 (2): 113-120.

14 Allard B. et al., Le Pharmacien Hospitalier et Clinicien (2013); 48 (4): 15-21.

15 Shintani H., Biomedical instrumentation & technology (1995); 29 (6): 513–519.

16 Hirata N. et al., Radiation Physics and Chemistry (1995); 46 (3): 377–381.

17 Golli-Bennour E. E. et al., International urology and nephrology (2011); 43 (2): 483–490.

18 Azzabi A. et al., Néphrologie & Thérapeutique (2014); 10 (5): 318.

19 Golli-Bennour E.E et al., World J Nephrol Urol (2017); 6 (1-2): 14-17.

20 da Silva Aquino K. A., INtechOpen (2012); www.intechopen.com/books/gamma-radiation/sterilization-by-gamma-irradiation (27.04.2018).

21 Dawids S., Handlos V. N., Developments in hematology and immunology (1989); 347–368.

22 Unpublished data from Fresenius Medical Care Deutschland GmbH: Internal calculation based on weight measurements before treatment of FX Dialyzers versus F-series dialysers.

23 Unpublished data from Fresenius Medical Care Deutschland GmbH: Internal calculation based on weight measurements of FME FX classix 80 versus FME HF 80S. The typical number of treatments in most clinics is approximately 10,000 per year; this results in about 1,600 kg less waste being produced annually with FX classix 80 when used on FME 5008 CorDiax machine.

24 EC-JRC-IES (2011): ILCD handbook – Recommendations for LCIA in the European context. Source: publications.jrc.ec.europa.eu/repository/handle/JRC61049 (all 15 environmental impact categories with recommendation in table 1 of this ILCD handbook have been evaluated).

25 Unpublished data from Fresenius Medical Care Deutschland GmbH internal study (2018): Comparative life cycle assessment of selected FME dialysers. Eco-performance is always calculated versus baseline product (FME HF 80S); long distance scenario illustrated.