FX high-flux and FX low-flux dialysers

Innovation at all levels

- State-of-the-art FX-class design

- Efficient removal of uraemic toxins with the Helixone® membrane

- INLINE steam sterilised

- Available in both low-flux and high-flux ranges

Key features

FX dialysers

A dialyser is often referred to as an “artificial kidney" in dialysis treatment. Its function is to remove any excess wastes and fluid from the blood, when the patient's kidneys can no longer perform that task.

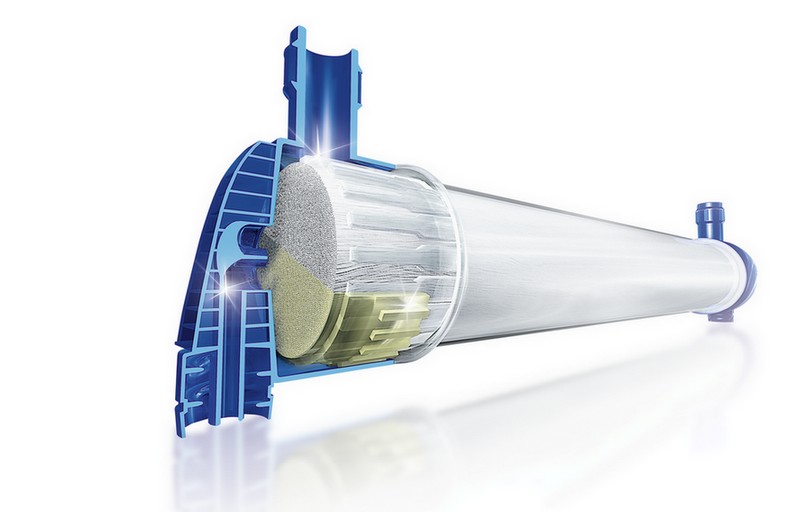

Several state-of-the-art technologies have been combined to create the distinctive, functional features of the FX dialysers. The fibre bundle geometry, the membrane nanostructure, the flow port and the housing design all provide advantages in terms of performance, haemodynamics, dialysate flow and safety and handling.

Lateral blood inlet ports provide a homogenous blood flow path

Improved design and refined haemodynamics

- The lateral blood inlet port provides a homogenous blood flow path, avoiding low velocity stagnation zones in the header region

- The risk of accidental kinking of bloodlines is very low

Radial dialysate flow

- The pinnacle structure of the polypropylene housing ensures a uniform dialysate flow around the entire fibre bundle

- A high packing density of the fibre bundle and a special wavy fiber structure avoid dialysate channeling

- Combined, these features enable the constant performance of all FX dialysers

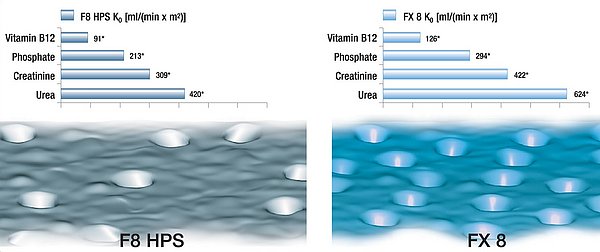

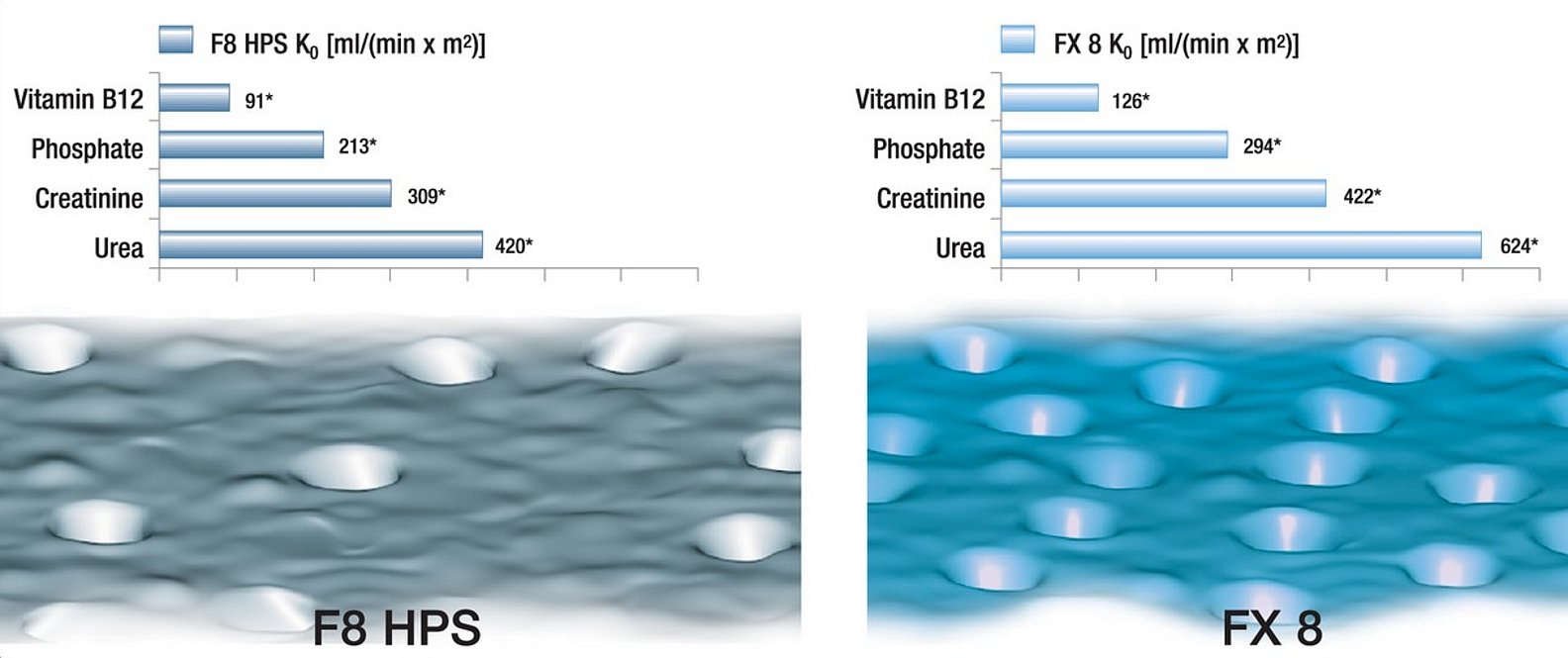

Optimum fibre dimensions

- The reduced inner diameter and wall thickness of the fibre increase the internal filtration and minimise diffusive resistance

- A significant increase of both the diffusive and convective clearances is therefore achieved, allowing for the efficient removal of a broad spectrum of uraemic toxins

Dialyser weight

- Dialyser weight is a crucial factor not only in logistics, but also in waste management

- The housing of FX dialysers is made of polypropylene. In comparison with the widely used polycarbonate, it is much lighter

- The result: FX dialysers weigh around half as much as most dialysers.

- FX60=105g

Technology

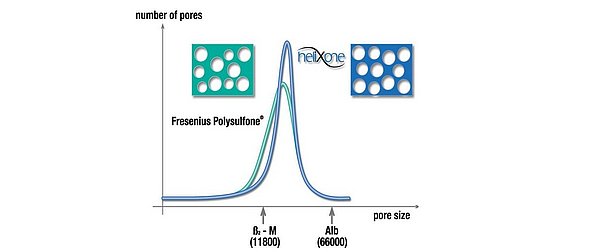

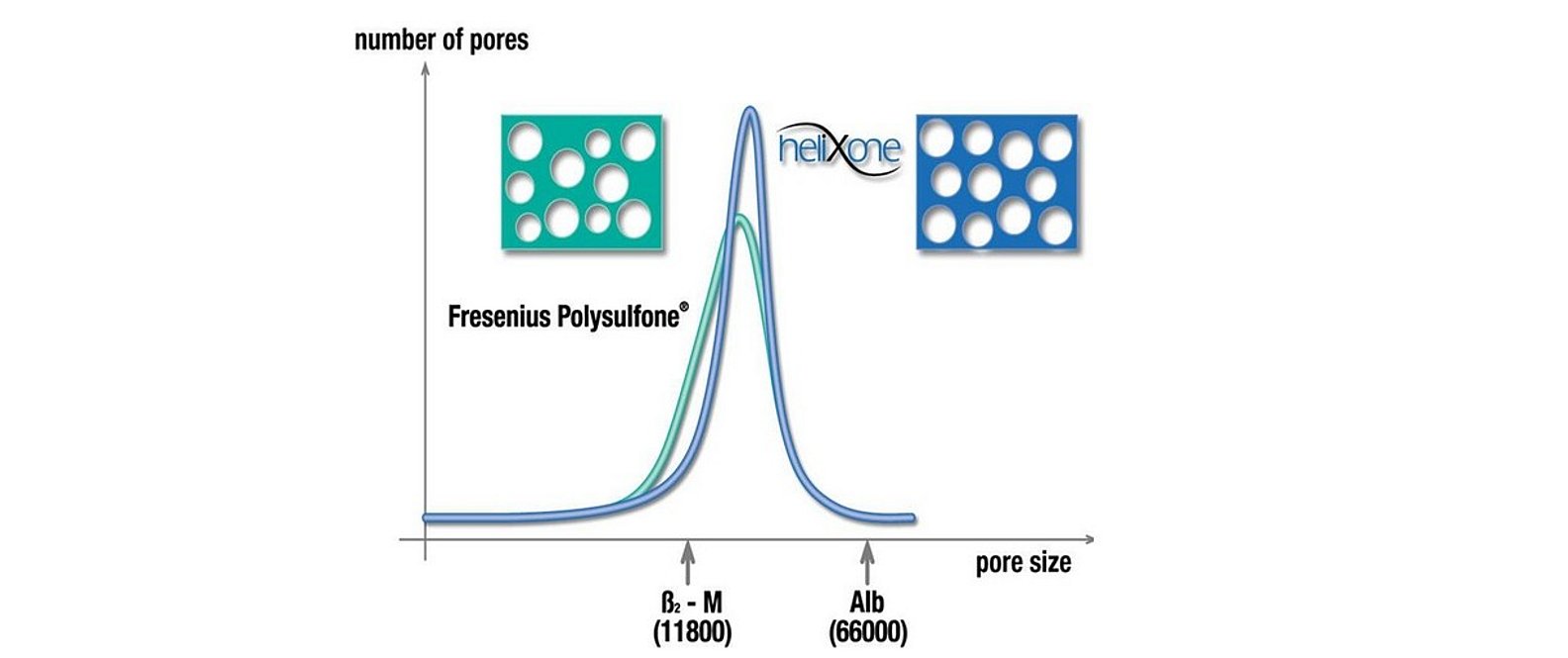

Helixone®: the advanced polysulfone membrane

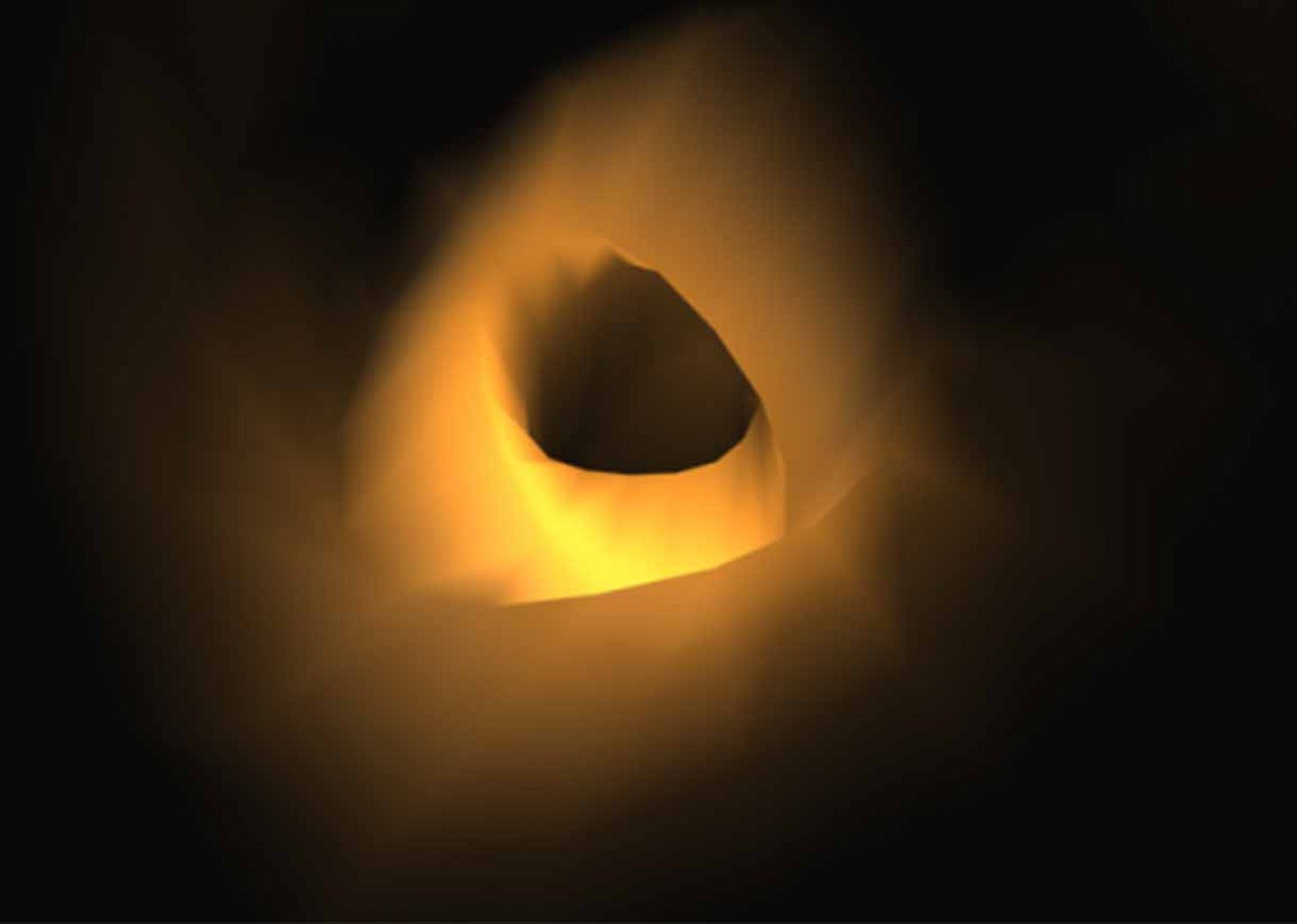

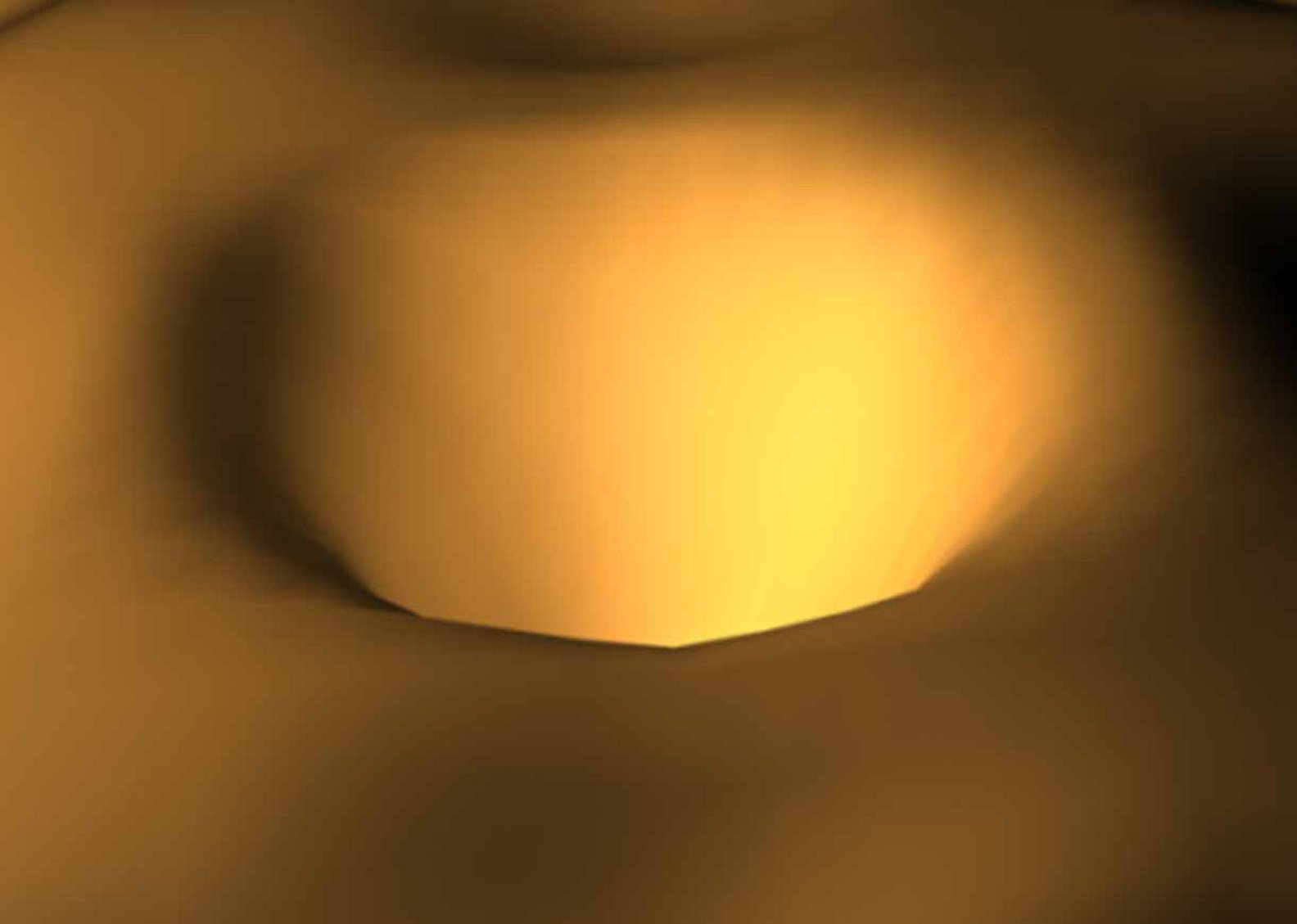

- Nanotechnology membrane fabrication procedures (Nano Controlled Spinning Technology, NCS™) provide Helixone® with a highly defined pore structure and distribution at the innermost, separating region of the membrane1,2

- Unlike conventional pores, which were rough and uneven in shape, the pores in the inner layer of the Helixone® membrane are smooth and cylindrical

- This reduces the molecules' resistance when travelling through the pores and allows for enhanced removal

Conventional pores

Helixone® pores

Helixone® has been specially designed to meet the demands of both low-flux and high-flux therapies:

- More even distribution of pores

- Estimated increased average pore size of 1.8 nm (low-flux) and 3.3 nm (high-flux)

- Increased performance per unit of surface area

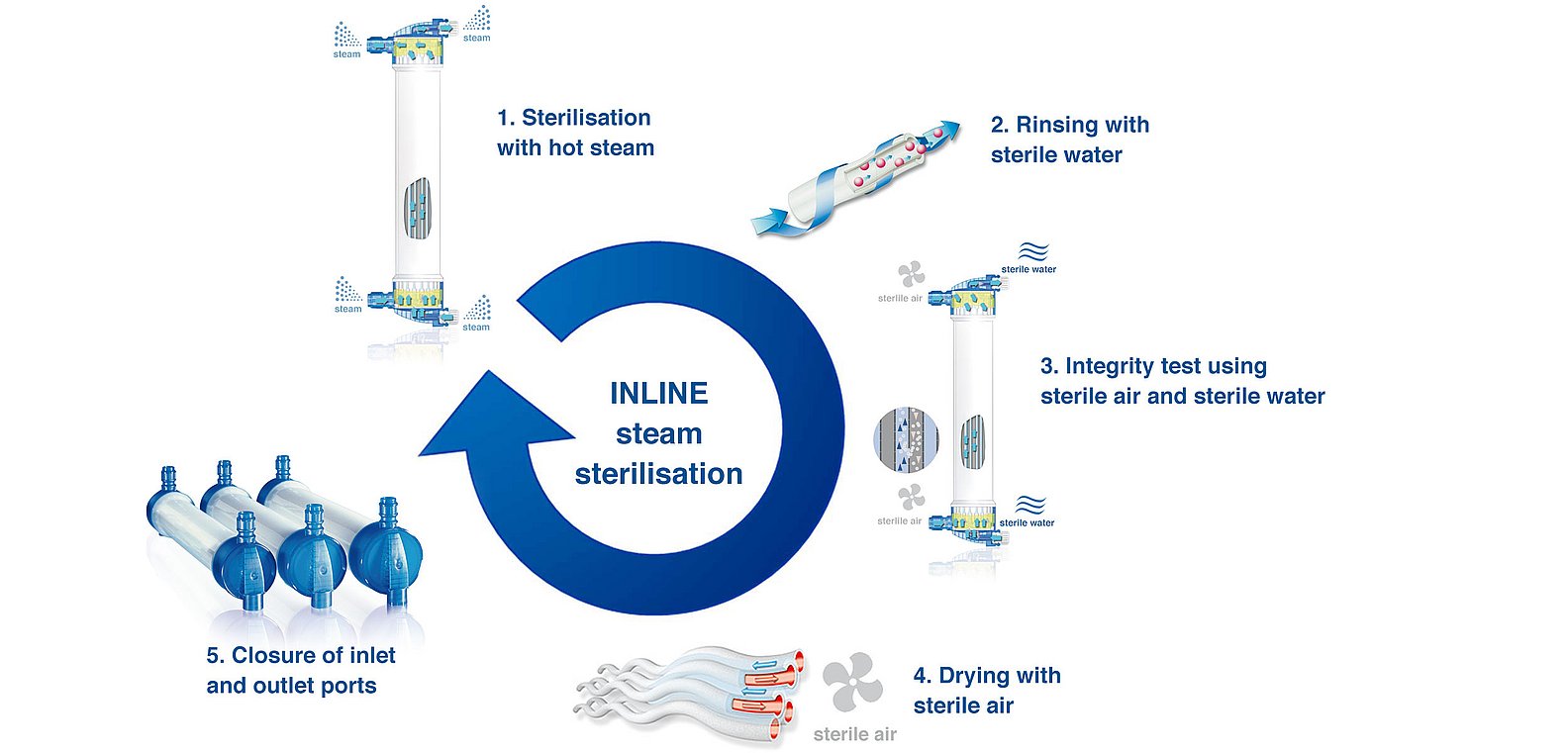

INLINE steam sterilisation – purity ensured

No chemical residues. Low rinsing volumes. Lower costs.

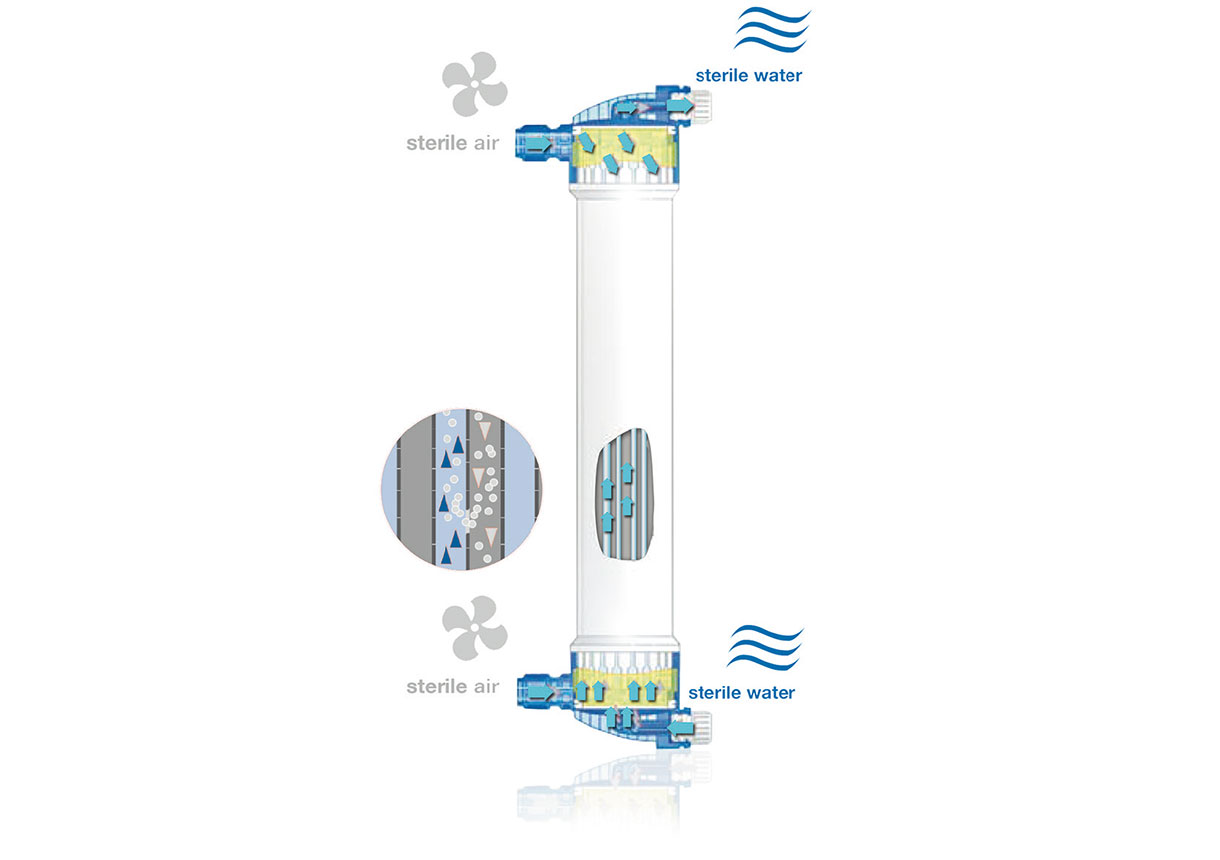

INLINE steam sterilisation process

INLINE steam sterilisation: how it works

- Both the blood and the dialysate compartment of the dialysers are rinsed continuously with steam at a temperature of 121°C for a minimum of 15 minutes, or a higher temperature for a shorter time, to ensure sterility.

- The dialyser is rinsed with sterile water

- Every dialyser is tested for fibre integrity using a bubble-point test

- The dialysers are dried with warm, sterile air

- Finally, after drying the blood inlet and outlet, ports are closed

INLINE steam sterilisation: the benefits

- Highly pure, sterile and pyrogen-free dialysers without any potentially harmful residues from sterilisation

- The biocompatibility of membranes remains unaffected by sterilisation

- The optimised use of resources due to low rinsing volumes: only 500 ml is required

- Dry dialysers with minimised risk of contamination due to microbial growth

Fibre integrity testing

- All dialysers have to pass the bubble point test as part of the INLINE steam sterilisation process

- Sterile air is forced into the dialysate compartment while the blood compartment contains sterile water

- If any leakages were present in the membrane, air would pass through the membrane and create bubbles

- Dialysers failing the integrity test are discarded

- This integrity test minimises the risk of fibre ruptures and the risk of blood leakages

Performance data

FX low-flux dialysers

| FX low-flux dialysers | FX 5 | FX 8 | FX 10 | |||

|---|---|---|---|---|---|---|

| Ultrafiltration coefficient (ml/h x mmHg) | 8 | 12 | 14 | |||

| Clearance: QB: (200 ml/min) | ||||||

| Urea | 180 | 191 | 193 | |||

| Creatinine | 165 | 178 | 181 | |||

| Phosphate | 141 | 160 | 170 | |||

| Vitamin B12 | 88 | 107 | 121 | |||

| Clearance: QB: (300 ml/min) | ||||||

| Urea | 228 | 254 | 261 | |||

| Creatinine | 200 | 225 | 231 | |||

| Phosphate | 164 | 194 | 210 | |||

| Vitamin B12 | 94 | 120 | 138 | |||

| Clearance: QB: (400 ml/min) | ||||||

| Urea | 293 | 303 | ||||

| Creatinine | 252 | 260 | ||||

| Phosphate | 213 | 233 | ||||

| Vitamin B12 | 126 | 146 | ||||

| The in vitro performance data were obtained with QD=500 ml/min: QF=0 ml/min; T=37°C (ISO 8637) The ultrafiltration coefficients were maintained using human blood, Hct=32%, protein content 6% | ||||||

| Effective surface area (m²) | 1,0 | 1,4 | 1,8 | |||

| Blood filling volume (ml) | 54 | 74 | 95 | |||

| Membrane material | Helixone® | |||||

| Housing material | Polypropylene | |||||

| Potting compound | Polyurethane | |||||

| Sterilisation method | INLINE steam | |||||

| Application | HD | |||||

FX high-flux dialysers

| FX high-flux dialysers | FX 40 | FX 50 | FX 60 | FX 80 | FX 100 | |

|---|---|---|---|---|---|---|

| Ultrafiltration coefficient (ml/h x mmHg) | 20 | 33 | 46 | 59 | 73 | |

| Clearance: QB: (200ml/min) | ||||||

| Urea | 170 | 189 | 193 | 197 | ||

| Creatinine | 144 | 170 | 182 | 189 | ||

| Phosphate | 138 | 165 | 177 | 185 | ||

| Vitamin B12 | 84 | 115 | 135 | 148 | ||

| Inulin | 54 | 76 | 95 | 112 | ||

| Clearance: QB: (300 ml/min) | ||||||

| Urea | 250 | 261 | 276 | 278 | ||

| Creatinine | 210 | 230 | 250 | 261 | ||

| Phosphate | 201 | 220 | 239 | 248 | ||

| Vitamin B12 | 130 | 155 | 175 | 192 | ||

| Inulin | 81 | 104 | 125 | 142 | ||

| Clearance: QB: (400 ml/min) | ||||||

| Urea | 303 | 362 | 331 | |||

| Creatinine | 262 | 287 | 304 | |||

| Phosphate | 248 | 272 | 284 | |||

| Vitamin B12 | 167 | 190 | 213 | |||

| Inulin | 109 | 133 | 152 | |||

| The in vitro performance data were obtained with QD=500 ml/min: QF=0 ml/min; T=37°C (ISO 8637) The ultrafiltration coefficients were maintained using human blood, Hct=32%, protein content 6% | ||||||

| Effective surface area (m²) | 0,6 | 1,0 | 1,4 | 1,8 | 2,2 | |

| Blood filling volume (ml) | 32 | 53 | 74 | 95 | 116 | |

| Membrane material | Helixone® | |||||

| Housing material | Polypropylene | |||||

| Potting compound | Polyurethane | |||||

| Sterilisation method | INLINE steam | |||||

| Application | HD/HDF/HF | |||||

FX haemodiafilters

| FX haemodiafilters | FX 600 | FX 800 | FX 1000 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ultrafiltration coefficient (ml/h x mmHg) | 52 | 63 | 75 | ||||||

| Clearance: QB: (200ml/min)QF: (0ml/min) | |||||||||

| Urea | 196 | 198 | |||||||

| Creatinine | 184 | 190 | |||||||

| Phosphate | 180 | 184 | |||||||

| Vitamin B12 | 141 | 149 | |||||||

| Inulin | 101 | 110 | |||||||

| Clearance: QB: (300ml/min) QF: (75ml/min) | |||||||||

| Urea | 284 | 289 | 290 | ||||||

| Creatinine | 262 | 271 | 280 | ||||||

| Phosphate | 254 | 262 | 269 | ||||||

| Vitamin B12 | 199 | 209 | 211 | ||||||

| Inulin | 150 | 161 | 164 | ||||||

| Clearance: QB: (400ml/min) QF: (100ml/min) | |||||||||

| Urea | 351 | 361 | 364 | ||||||

| Creatinine | 313 | 328 | 343 | ||||||

| Phosphate | 301 | 313 | 325 | ||||||

| Vitamin B12 | 229 | 241 | 244 | ||||||

| Inulin | 172 | 185 | 188 | ||||||

| The in vitro performance data were obtained with QD=500 ml/min: T=37°C (ISO 8637) The ultrafiltration coefficients were maintained using human blood, Hct=32%, protein content 6% | |||||||||

| Effective surface area (m²) | 1,5 | 1,8 | 2,2 | ||||||

| Wall thickness/inner diameter (µm) | 35/210 | ||||||||

| Blood filling volume (ml) | 97 | 118 | 138 | ||||||

| Membrane material | Helixone® | ||||||||

| Housing material | Polypropylene | ||||||||

| Potting compound | Polyurethane | ||||||||

| Sterilisation method | INLINE steam | ||||||||

| Application | HD/HDF | ||||||||

If you would like to order this product via the NHS Supply Chain Catalogue, please visit the following link: NHS Supply Chain Online Catalogue

Additional information relating to multiBic or Calrecia can be found in the critical care section of our product information page.

Adverse Events Reporting

Adverse events should be reported. Reporting forms and information can be found at

https://yellowcard.mhra.gov.uk/ or search for MHRA Yellowcard in the Google Play or Apple app store. Adverse events should also be reported to Fresenius Medical Care on 01623 445100.

UK/HEMA/FME/0922/0005 Date of Preparation: November 2022

1 Bowry, S.K.: Nano-controlled membrane spinning technology: Regulation of pore size, distribution and morphology of a new polysulfone dialysis membrane. In Hemodialysis Technology (eds: Ronco, C., La Greca, G.) Contributions to Nephrology, Vol. 137: 85-94 (2002)

2 Ronco, C., Nissenson, A.R.: Does nanotechnology apply to dialysis? Blood Purification 19: 347-352 (2001)