Environment

We take responsibility for our environment.

As a global player in the health care sector, our responsibility extends beyond our business operations. We monitor the environmental performance of our operations globally and aim to use resources efficiently. At the same time, we need to ensure that the safety and quality of our products and services are not compromised.

Environmental protection

In our Global Environmental Policy, we commit to using natural resources as efficiently as possible. The policy also includes our commitment to business practices that promote the protection of the environment and the minimization of any adverse environmental impact of our business. We strive for continuous improvement in our environmental performance. Around the globe, we monitor environmental data from our dialysis clinics and production sites.

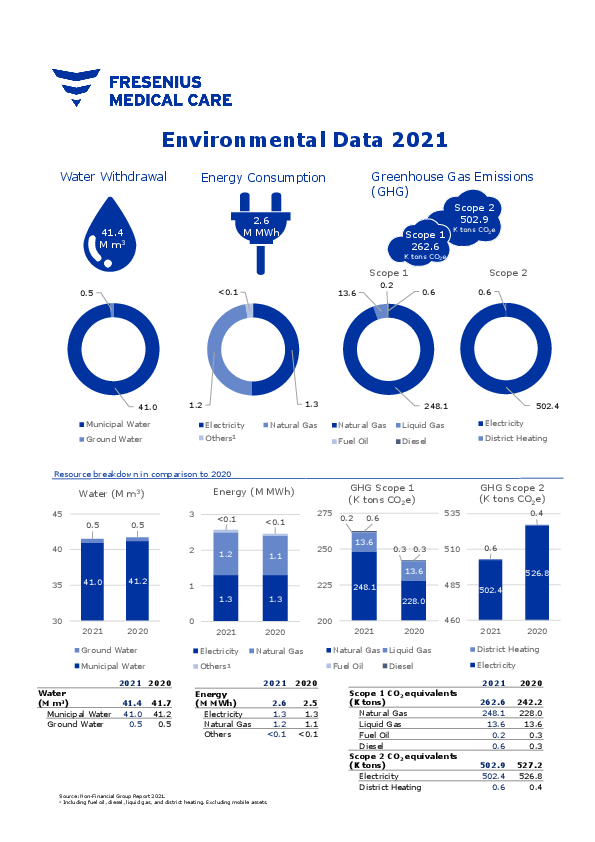

We commit to become climate neutral for both Scope 1 (direct) and Scope 2 (indirect) emissions by 2040. Additionally, we have set an interim target to make sure we stay on track - by 2030 we aim to half Scope 1 and Scope 2 emissions compared with reported emission levels in 2020. We are also continuously assessing our emissions across the entire value chain (Scope 3 emissions) to identify further possible reduction targets. Our climate targets are in line with the Paris Agreement’s goal to limit global temperature increase to 1.5 °C.

Environmental initiatives

To continuously improve our environmental performance, we are involved in local sustainability projects which we report as part of our global Green & Lean initiative.

Green and Lean initiatives enable best practices to be shared between plants with a view to using natural resources efficiently and implementing environmentally sustainable operations.

Green & Lean initiatives 2021

More than 100 environmental initiatives were reported at our production sites around the world.

More than 20,000 MWh of energy saved,

0.8 % of total energy consumption

Nearly 5,500 tons of CO2e emissions prevented,

0.7% of total emissions

220,000 m³ of water saved,

0.5% of total water consumption

About 700 tons of waste recycled or reused

All figures are rounded.

Data on total waste is currently not reported on a global level but will be in scope for future reporting.

Reducing environmental impact along the product life cycle

At Fresenius Medical Care, innovations and new technologies help us to reduce our impact on the environment and the use of resources. Most of the water we use is to produce dialysate for life-saving dialysis treatment in our dialysis clinics around the world. The amount of dialysate and consequently the amount of water required per dialysis treatment is determined by a variety of factors including blood flow rate, the selected dialyzer, and the treatment method, most of which are the direct responsibility of the physician. In our efforts to save resources, we continue to prioritize the quality of our care and our products. Our latest dialysis machine generations, the 5008 and 6008 series, are both designed to be more eco-efficient. These machines automatically adjust the dialysate flow to the patient’s blood flow, which allows us to save significant amounts of dialysate, water, and energy while maintaining a consistently high dialysis quality.

Ecologically sustainable dialysis products

We are continuously working to make our products and processes more environmentally friendly, for example by using new materials with improved environmental properties or developing new technologies that further reduce the resource consumption of our dialysis machines. The aim is to provide our customers with added value by helping them save on costs or to better fulfill environmental requirements.

Many parts of life-sustaining dialysis machines are reused and recycled. Dialysis machines are disassembled, allowing the recycling of various materials and components, including bulbs, plastics and circuit boards.

Recycling is one of the easiest ways to have a positive impact on our environment. Our dialysis machine recycling process helps with our mission to care for the well-being of our patients, our staff and our planet.

Eco-friendly products made of Biofine®

The first environmentally friendly products were introduced in 1996 with the stay.safe® CAPD system made of 100% Biofine®. Many other PVC-free products have followed since then.

Biofine® is a seven-layer polymer constructed from hydrogen and carbon atoms. That means it...

- is free of PVC and plasticizer,

- requires less material for production as it is 60% thinner than PVC,

- creates less waste,

- requires less energy for production,

- does not release hydrochloric acid upon incineration, and

- is easily recyclable.

Based on all these qualities, Biofine® has received global recognition, including a valuable certification from the Nordic Ecolabel organization. Biofine® is used in the majority of Fresenius Medical Care’s products for peritoneal dialysis.